It's Easier Here.

Leith Cars Blog

Electric Vehicle (EV) battery cells aren’t cheap, but the good news is that the average cost of lithium-ion batteries has fallen a whopping 89% since the year 2010, according to BloombergNEF, (a strategic research provider that covers global commodity markets and the technologies used to transition to a low-carbon economy). The average price of a lithium-ion (Li-ion) EV battery pack in 2010 was a staggering $1,200 per kilowatt-hour (kWh) but was a more reasonable $132/kWh in 2021.

So what do all those numbers mean, exactly? Let’s dive in.

EV battery packs are made up of multiple interconnected modules consisting of tens to hundreds of rechargeable Li-ion cells. Together, these cells make up about 77% of the total cost of an average battery pack.

So, what drives the cost of these individual battery cells? It’s all about the cathode; each cathode adds up to over half of the overall cost of a battery cell. But what’s a cathode, you ask?

A cathode is one of two electrode types found in a battery or an electrochemical cell. The other type is called the anode; together, they create the flow of electric charge. The cathode is the positive electrode, while the anode is the negative electrode.

The type of material that makes up the cathode determines a battery’s capacity, range, power, and thermal safety (and the EV where it resides). Most cathodes contain Lithium and other metals like Nickel, Cobalt, and Manganese.

Automakers are rushing to secure supplies of these in-demand metals as EV sales continue to grow, making them a bit costly as a high-demand commodity. It also doesn’t help that the majority of Cobalt, mined in the world, comes from the Democratic Republic of Congo (DRC) where child labor is often used. DRC mined Cobalt accounted for 73% of global output in 2022. That percentage of production is expected to drop to 57% by 2030, according to the Cobalt Institute, as other nations, like Indonesia, ramp up their mining efforts.

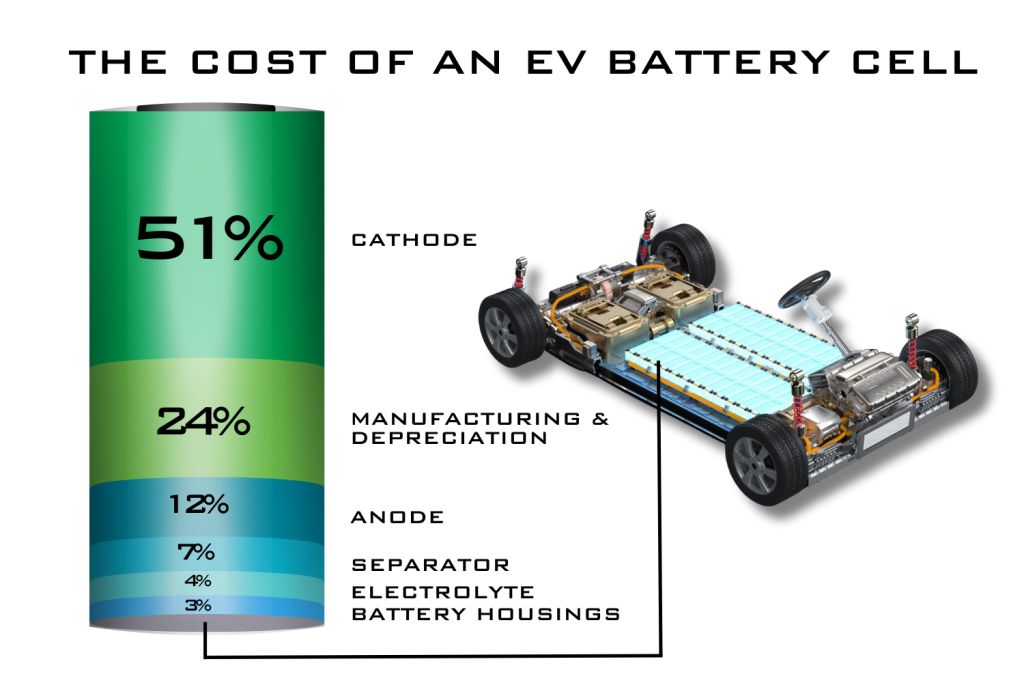

In the image below, you can see what materials and other factors make up the cost of an EV battery, with the cathode taking up the greatest proportion at 51%.

EV Battery Cell Components other than Cobalt

Components outside of the cathode make up the other 49% of a battery cell’s cost. This includes the manufacturing process and depreciation (24%), which involves producing the electrodes, assembling the different components, and finishing the cell. Globally, China produces 80% of Electric Vehicle battery cells, while the United States only produces 6%.

The anode makes up 12% of the total cost. The anode in a Li-ion cell is usually made of natural or synthetic graphite, which helps keep the cost down compared to other battery commodities.

At 7% of the EV battery’s cost, the separator performs the important function of preventing electric contact between the cathode and the anode.

The electrolyte makes up 4% of the battery’s cost and is the medium that transports lithium ions from the cathode and the anode.

Finally, the battery housings that contain and protect battery packs account for 3% of the total cost and are usually made of steel or aluminum.

So while the cost per kilowatt-hour has been going down for EV batteries, more and more Electric Vehicles are being produced, which will cause a much greater demand for batteries and the specialized materials they require in the near future. How this will all play out cost-wise is anyone’s guess, but currently, the average cost of the battery pack in your new EV is between $10,000 and $12,000. But don’t worry; today’s battery packs are expected to last between 15 and 20 years or 100,000 to 200,000 miles (depending on your driving behavior), which is far longer than most people keep their cars.

By Mark Arsen, LeithCars.com

More from my site